At the recent Western Australia (WA) Professional Development Forum (PDF), fleet management professionals shared their knowledge on two crucial aspects of fleet operations: building robust supplier relationships and harnessing technology to enhance driver safety.

The panel featured Michael Kemp, Managing Director and CEO of Osmose Australia; Dave Robinson, Fleet Manager for Western Power; and Sam Latella, Coordinator Fleet Services for the City of Bayswater. The session was facilitated by Paul Sor, National Asset Manager for the Australian Red Cross who guided the discussions and ensured a comprehensive exploration of the topics. Here’s a detailed look at the key takeaways from their discussions.

Building Strong Supplier Relationships

Establishing strong supplier relationships is fundamental to effective fleet management. The panel highlighted how trust and mutual understanding are critical particularly during the COVID-19 pandemic.

For the Red Cross, for example, their suppliers ensured they had access to essential vehicles despite significant shortages. This shows that nurturing and maintaining reliable supplier connections provides long term benefits for example having access to stock during times of crisis or uncertainty in the industry. For fleets and suppliers, trust extends beyond mere transactions. It involves a deeper, strategic partnership where both parties align their goals and expectations.

How to Foster Strong Supplier Ties

- Open Communication: Regular face-to-face meetings are crucial for building and maintaining trust. The panel shared that understanding suppliers’ internal drivers and sharing your own organisational goals can create a more collaborative environment. For instance, discussing long-term objectives and operational challenges openly helps suppliers tailor their services to better meet your needs.

- Transparency: Being upfront about what you need and expect from suppliers helps prevent misunderstandings. They emphasised that transparent communication ensures alignment and prevents potential conflicts. Clear expectations regarding delivery schedules, quality standards, and service levels are essential for a successful partnership.

- Personal Connections: Adding a personal touch can strengthen supplier relationships. Often, small, thoughtful gestures can make interactions more memorable and positive. Such personal connections foster goodwill and reinforce a sense of partnership. This assists with staff satisfaction across both organisations.

Overcoming Roadblocks to Building Strong Supplier Relationships

Building solid relationships with suppliers can be tricky, especially when long-term connections can sometimes lead to complacency. When suppliers know they have a steady stream of business, they might not always put in their best effort. To combat this, the panel advised regularly reviewing how suppliers are performing and keeping a competitive edge by considering new options. This ensures that suppliers remain motivated and continue to provide top-notch service. Additionally, councils often face internal challenges, such as adhering to strict policies and transparency requirements, which can slow things down and complicate the process.

To tackle these issues, councils should aim to simplify their internal processes while still following necessary rules and policies. Using digital tools to manage tenders and being upfront with suppliers about any constraints can help make things smoother. By staying engaged, setting clear expectations, and working together towards mutual goals, councils can build strong, effective relationships with suppliers that support their needs and serve the community well. Softer criteria like reliability, service levels etc can also be built into tender assessment criteria.

Embracing Technology for Driver Safety

The integration of technology is revolutionising fleet management, particularly in enhancing driver safety. Using telematics and driver-facing cameras prove to be a game-changer in monitoring and improving driver behaviours.

Furthermore, focusing on driver education rather than punitive measures has led to better safety outcomes and strengthened trust within their team. Technology provides real-time data that helps identify risky behaviours and offers opportunities for constructive feedback and training.

However, technology, especially driver-facing cameras, raises important privacy concerns. Ensuring that camera data is used strictly for safety purposes and is accessible only by limited trusted senior staff is imperative to to successful mobilisation. This approach helps maintain transparency and build trust with drivers. Clear policies on data usage and privacy can alleviate concerns and foster acceptance of new technologies.

The panel also discussed that implementing technology requires a shift in organisational culture. Technology should support and empower drivers rather than merely monitor them. Providing actionable feedback and focusing on performance improvement leads to better safety outcomes and greater acceptance of technology. Creating a supportive environment where technology is seen as a tool for enhancement is crucial for successful integration.

Addressing Safety in Hazardous Environments

Safety remains a major concern in hazardous environments, such as during storms or when working with heavy equipment. Workers operating elevated work platforms (EWPs) in adverse weather conditions face significant risks. To mitigate these risks, organisations are increasingly adopting advanced safety technologies.

For example, reverse radars and anti-rollaway brake systems are integrated into heavy vehicles to prevent accidents. These systems automatically engage brakes if a person enters a danger zone while the vehicle is reversing, thus reducing the likelihood of incidents similar to the tragic case reported in Queensland where a worker was run over by a reversing vehicle.

Meanwhile, the rollout of safety features often involves overcoming several challenges, particularly when working with OEMs and suppliers. Customised safety solutions, such as advanced radars and braking systems, may be necessary to address specific safety needs. Effective supplier management ensures competitive and fair assessments, with constructive feedback encouraging continuous improvement.

Maintaining relationships with OEMs requires balancing competitive pricing with high-quality, timely service. Transparent communication helps secure vehicles even during fluctuating demand. Aligning vehicle specifications with operational needs and securing build slots in a timely manner helps avoid delays.

Organisations must also be prepared for long lead times and potential delays in vehicle deliveries. This requires close collaboration with OEMs to ensure that vehicles are delivered on time and meet the required specifications. Building strong relationships with OEMs and suppliers can help mitigate these challenges and ensure smoother fleet operations.

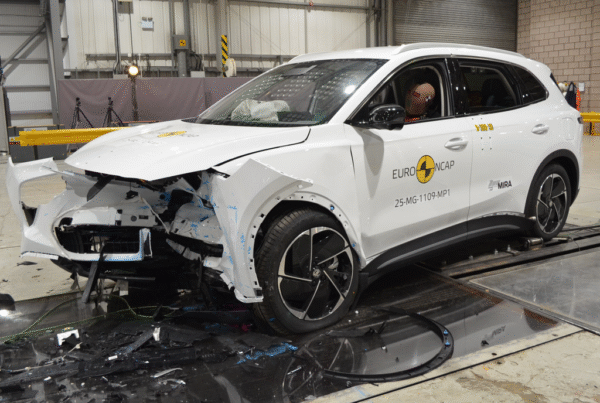

ANCAP Ratings and Safety Standards

While ANCAP (Australasian New Car Assessment Program) ratings are a key factor in safety policies for passenger vehicles, they are less applicable for heavy vehicles. Organisations like Western Power focus on developing their own safety specifications based on operational requirements and industry standards. This approach ensures that safety features are tailored to specific operational demands, providing enhanced protection in challenging environments.

Customising fleet specifications beyond ANCAP ratings helps address unique operational risks. This may include modifying vehicles beyond their original ANCAP ratings to align with operational requirements. By focusing on custom safety solutions, organisations can address unique risks associated with their operations and enhance overall safety.

Future Considerations and Industry Trends

The automotive industry is undergoing significant changes as governments implement policies to phase out internal combustion engines (ICEs) in favour of electric vehicles (EVs). Fleet managers face uncertainty regarding the residual values of ICE vehicles and must evaluate the total cost of ownership, including purchase price, maintenance, and future depreciation. Retaining assets for a longer period may offer strategic advantages in managing total costs amidst evolving regulations.

While organisations increasingly adopt eco-friendly practices, they also need to balance its financial implications. The use of low-rolling resistance tyres and hybrid vehicles addresses both environmental goals and operational constraints. Transitioning to EVs or plug-in hybrids presents challenges such as inadequate charging infrastructure but offers long-term benefits for sustainability.

Policies for EV charging vary, with some organisations providing home chargers and others relying on depot-based solutions. Effective infrastructure management is essential for smooth operations and employee satisfaction. Leveraging telematics and data analytics helps optimise fleet performance and manage maintenance costs.

When it comes to enhancing risk management, ongoing risk assessments and feedback from field teams are vital for refining safety measures. Addressing distractions, such as those caused by hands-free devices, and implementing comprehensive safety policies contribute to overall driver safety and operational efficiency.

Conclusion

The WA PDF provided valuable insights into fleet management, focusing on the importance of strong supplier relationships and the role of technology in driver safety. Building trust with suppliers through clear communication and personal connections is crucial, especially in challenging times. On the technological front, tools like telematics and driver-facing cameras can significantly improve driving habits while addressing privacy concerns.

The forum also highlighted the need to adapt safety measures to specific risks and industry changes, such as the shift to electric vehicles. As fleet managers face these evolving challenges, the key to success lies in maintaining strong supplier ties, embracing technology wisely, and continually refining safety practices to balance operational needs with environmental goals.

Did you find this article interesting? Click the ‘heart’ button above to give it a ‘like’!