A new type of battery could soon change how electric vehicles (EVs) are made and sold. Called lithium manganese-rich (LMR), this advanced battery promises longer range, lower costs, and less reliance on rare, expensive metals.

LMR batteries use more manganese and less cobalt and nickel than today’s standard batteries. This makes them cheaper to produce while still offering high performance.

Most EV batteries today rely on materials like nickel and cobalt, which are costly and hard to source responsibly.

LMR batteries solve this by increasing the amount of manganese, which is more affordable and easier to find. Using more manganese also reduces the need for cobalt, which is often linked with environmental and ethical concerns.

According to General Motors (GM), which is developing the battery, this chemistry could become a leading low-cost option for the North American market.

“We think that LMR really has an opportunity to be the low-cost chemistry in North America,” said GM battery engineer Andrew Oury.

More Range for Less

LMR batteries can deliver over 640 kilometres of driving range, more than most current lithium iron phosphate (LFP) batteries, which usually cap out at 560 kilometres.

GM says its test batteries have 33 per cent more energy density than top-performing LFP batteries. This means drivers could go further on a single charge or enjoy smaller, lighter battery packs with the same range.

“LMR has cost that’s comparable to LFP, but instead of having a capped range, we can get well over 400 miles [640 km],” said Mr Oury.

Fast, Flexible Production

One major advantage of LMR batteries is that they can be made using the same equipment already used for existing nickel-manganese-cobalt (NMC) battery production.

This means manufacturers like GM can avoid building new factories and instead adapt their current facilities, saving time and money.

“That’s a big benefit to localising low-cost chemistry. LFP wouldn’t be able to use the same manufacturing lines – it needs different lines,” said Mr Oury.

Commercial production of LMR batteries is expected to begin in 2028 at GM’s joint-venture plants with LG Energy Solution.

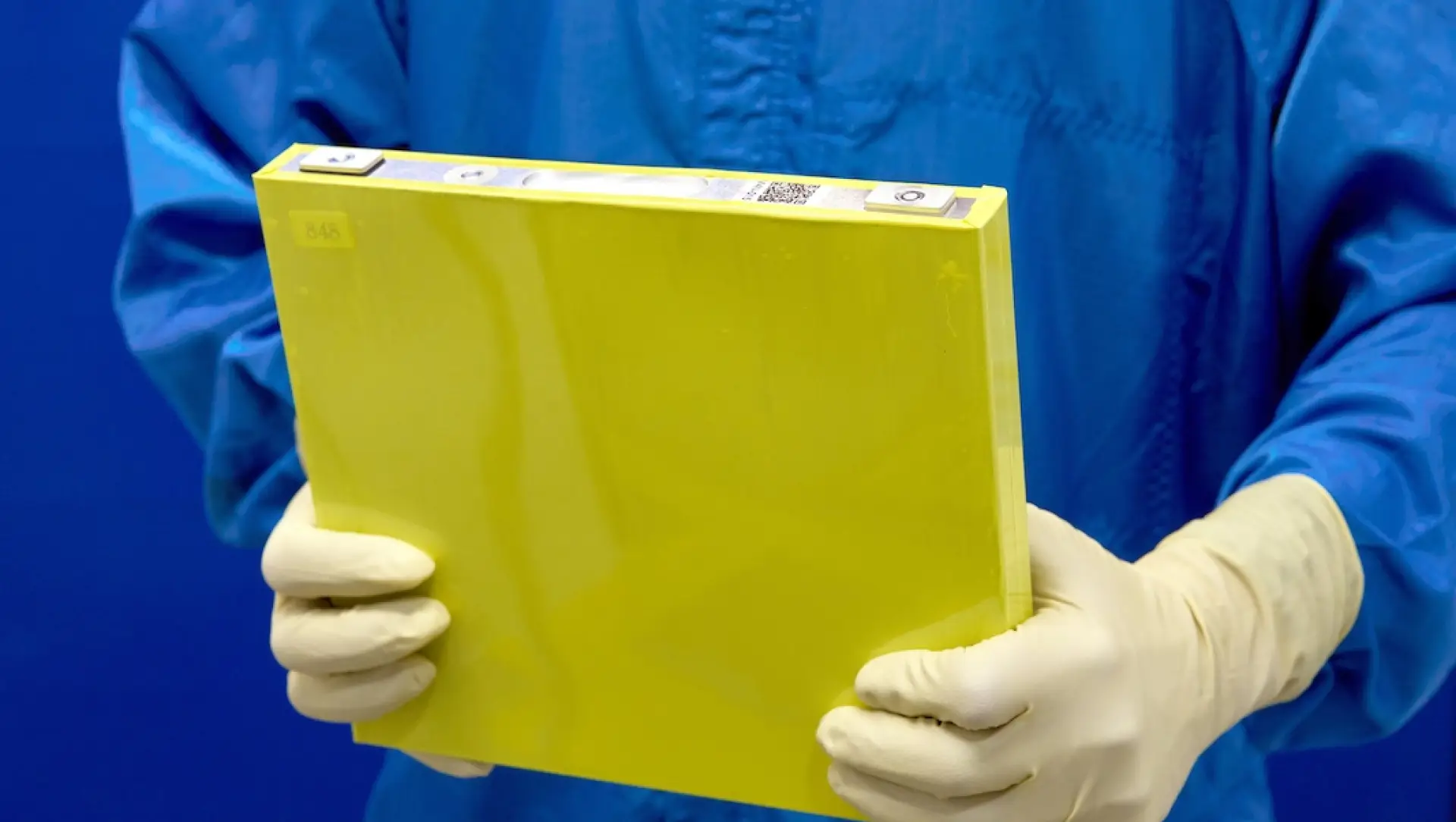

Smarter Cell Design

GM is also changing how battery cells are built. The company is moving to prismatic cells, which are larger and easier to pack into vehicles.

In electric trucks like the Chevrolet Silverado EV, GM can now reduce the number of battery modules from 24 to just 6, cutting the total number of parts by 75 per cent. This could lead to lower production costs and simpler maintenance.

Multiple Battery Options

Even with LMR batteries on the way, other chemistries like LFP and NMC will remain part of the mix. LFP batteries will power budget-friendly cars like the next-generation Chevrolet Bolt, while high-end models like the Cadillac Lyriq will continue using NMC batteries.

LMR batteries will fit into mainstream EVs that need good range at a lower price.

“We can now have an engineering segment for this segment and a modified one for that,” said Mr Oury.

“We’ll still have large economies of scale, but bring our costs down by being more application-specific.”

Battery Innovation at Full Speed

Despite slowdowns in global EV growth, GM is investing heavily in new battery technology. It has opened a battery innovation centre in Michigan and is building a battery development centre that can produce thousands of cells each year.

“This plant will look like a fraction of one of these [large] plants,” said Mr Oury. “It’ll have equipment that’s largely the same, that can help us bridge that gap between prototype manufacturing and full-scale manufacturing.”

GM is also expanding its EV line-up, with models like the Chevrolet Equinox EV, GMC Sierra EV, and Cadillac Lyriq rolling out across the US, China, and Australia.

Did you find this article interesting? Click the ‘heart’ button above to give it a ‘like’!